■ Welding/reliability testing

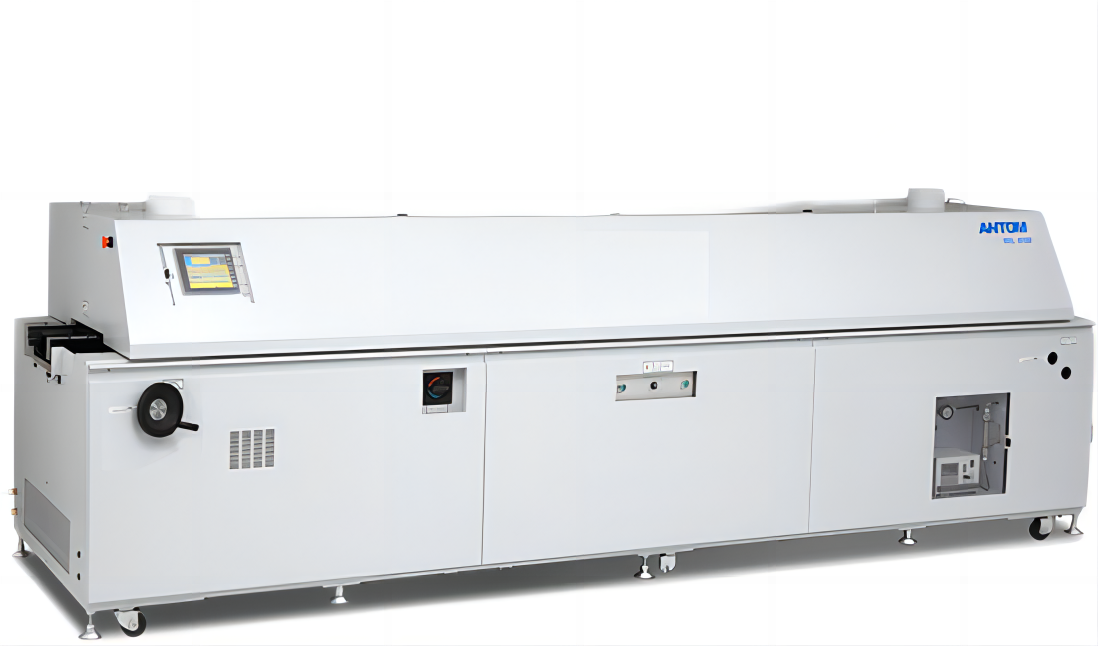

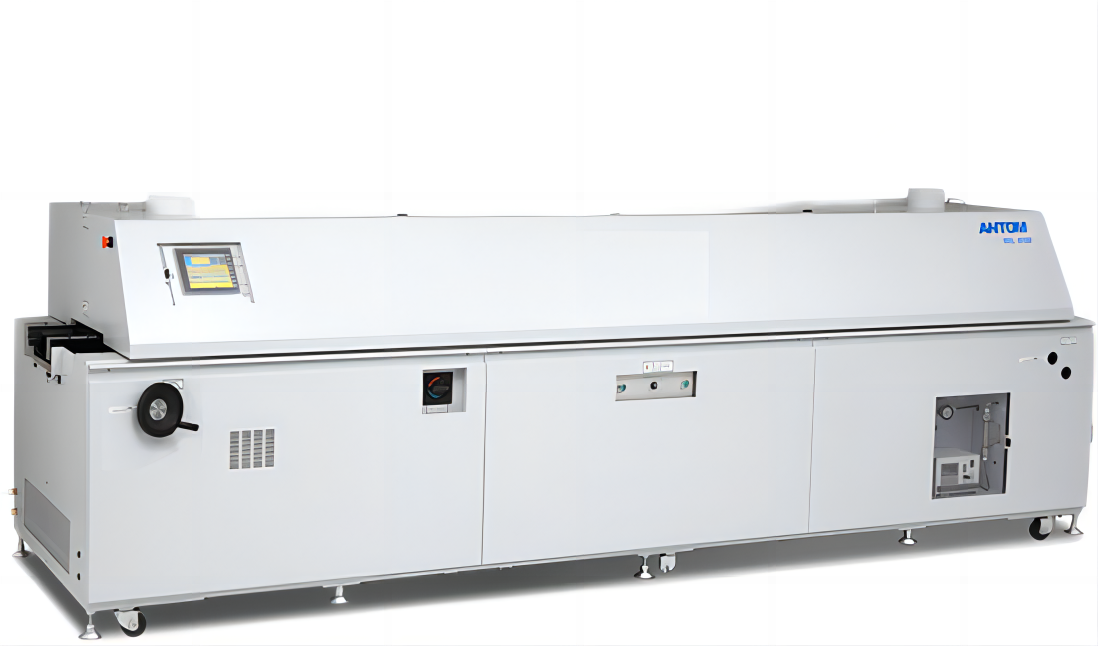

■ SOL-6136

■ SOL-8130

■ SOL-8150

Heating method: hot wind I infrared compound heating, strong temperature control, the temperature difference between the two warm areas can reach 50 ℃ -80 ℃

■ Configuration of the heating area: preheating area, return area and cooling area

■ Save energy, greatly reduce the cost and small equipment, and reduce the space occupying space

■ Unique rail transmission vibration design, vibration<1g

■ Lead -free process corresponding to high -performance return furnace

| Device model | The heating area | Handling speed | N2 supply (standard) | Oxygen concentration | The power supply | The device size(L*W*H mm) |

| SOL-6136 | Three preheating zones, three reflux zones and one cooling zone | 0.3~1.5m/min | 250L/min | 500ppm | AC200V?3φ ?56KVA?161A | 2993×1300×1306 |

| SOL-8130 | Five preheating zones, three reflux zones and one cooling zone | 0.3~1.5m/min | 250L/min | 500ppm | AC220V?3φ?38KVA?100A | 3980×1150×1305 |

| SOL-8150 | Five preheating zones, three reflux zones and one cooling zone | 0.3~1.5m/min | 250L/min | 500ppm | AC220V?3φ ?45KVA?130A | 3985×1380×1305 |